Research

Project Videos

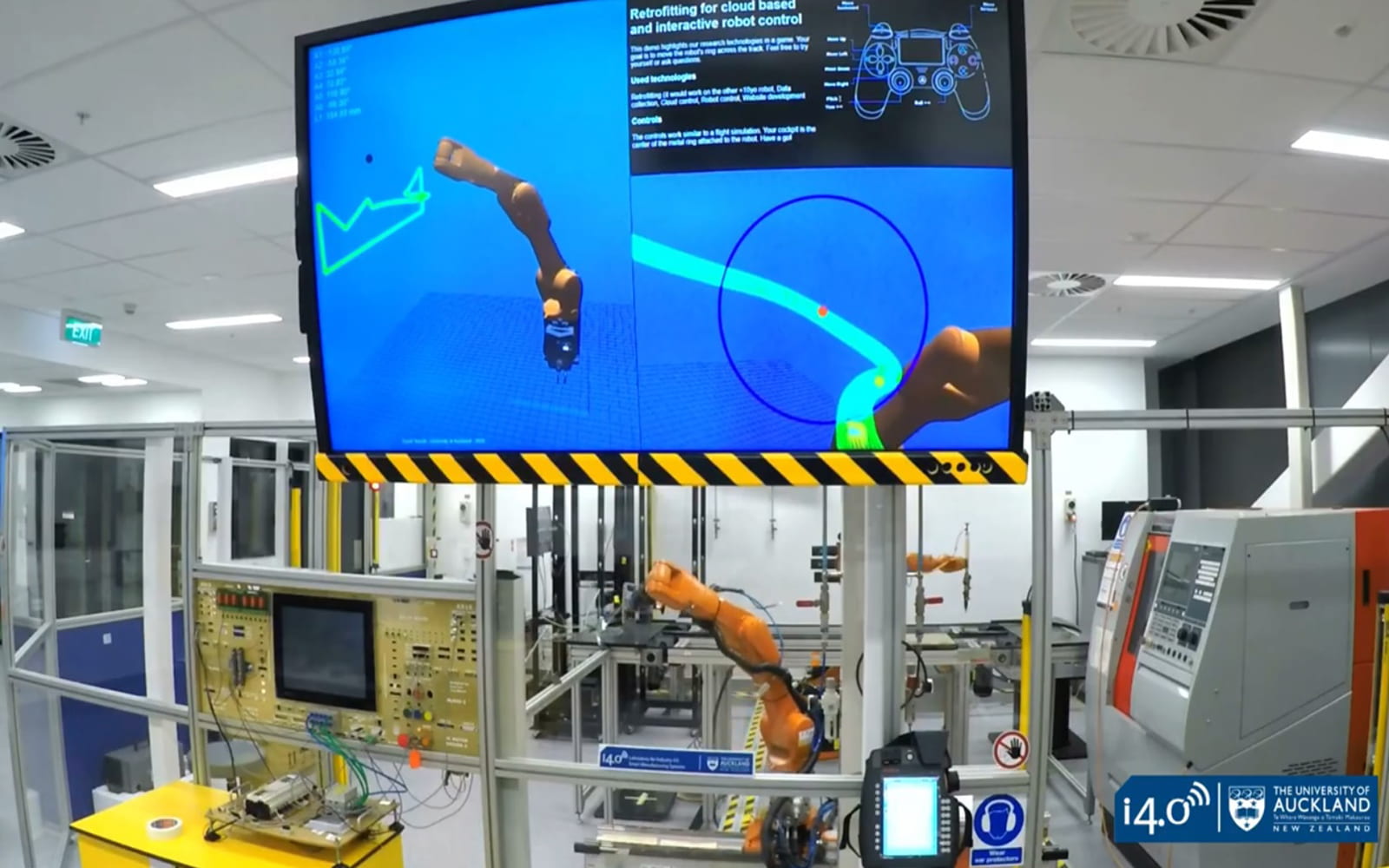

Retrofitting for Cloud-Based and Interactive Robot Control

HoloLens AR Visualllisation on CNC Machine

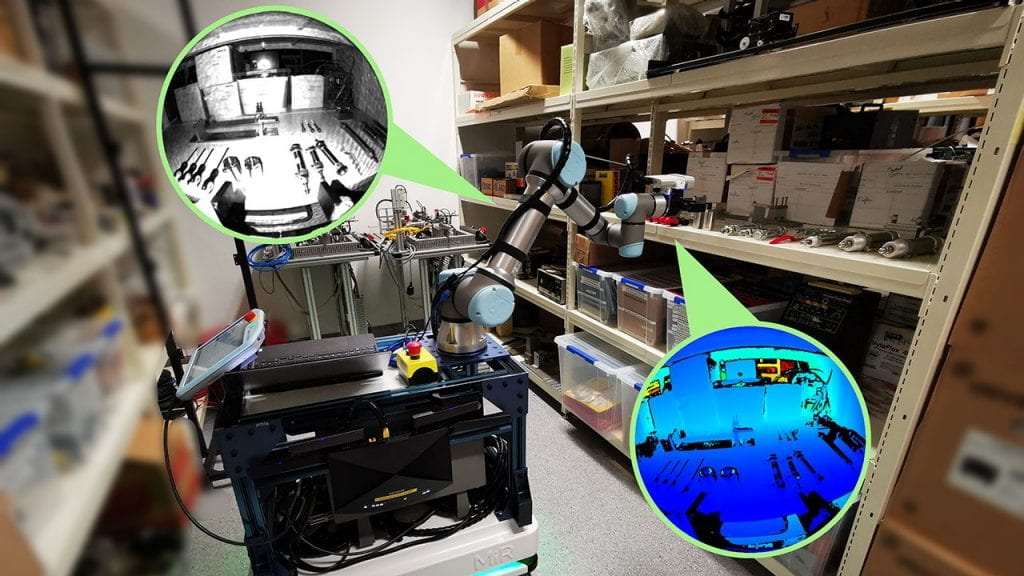

Intelligent factory collaborative robot in action

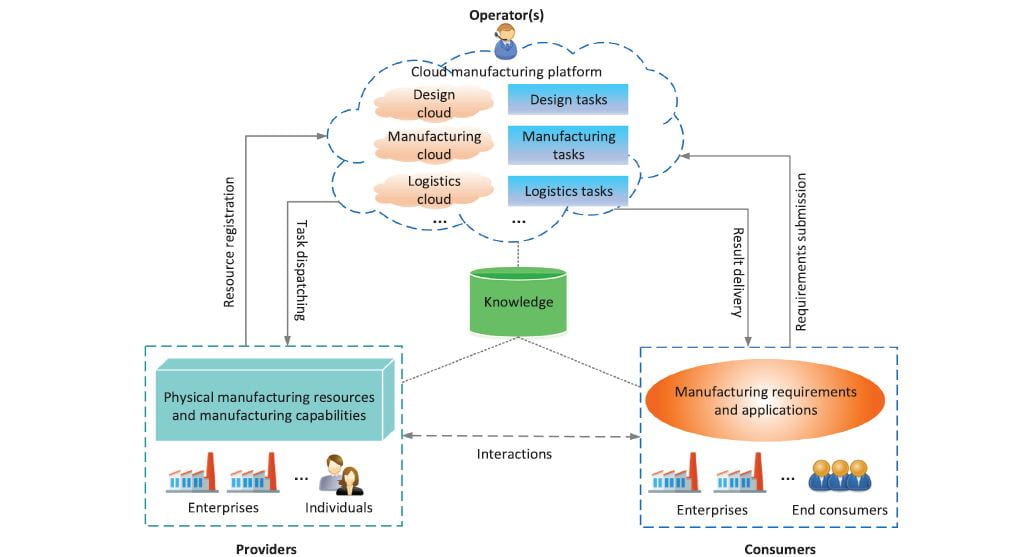

mCloud – A Cloud Manufacturing Solution

UR5 Collaboration

Digital Twin of KUKA Robot – Part 1

3D Printing Optimisation based on Machine Learning

Kuka cell manufacturing and assembly automation (LISMS)

iWindow – AR Process Monitoring

Research Areas

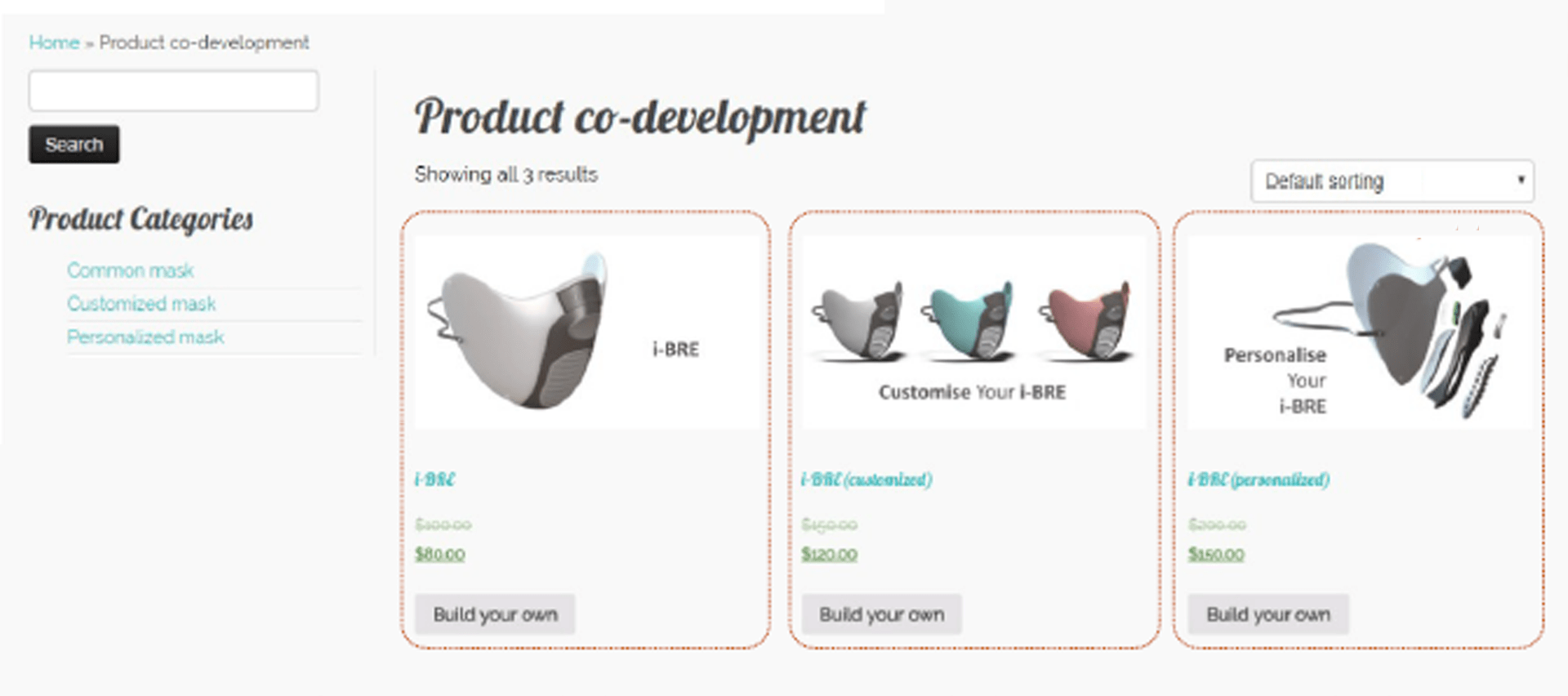

Smart Product Development

IoT-enabled rapid development of personalized product

Cyber-physical Production System

Merge the physical and digital realms towards cybernetic manufacturing

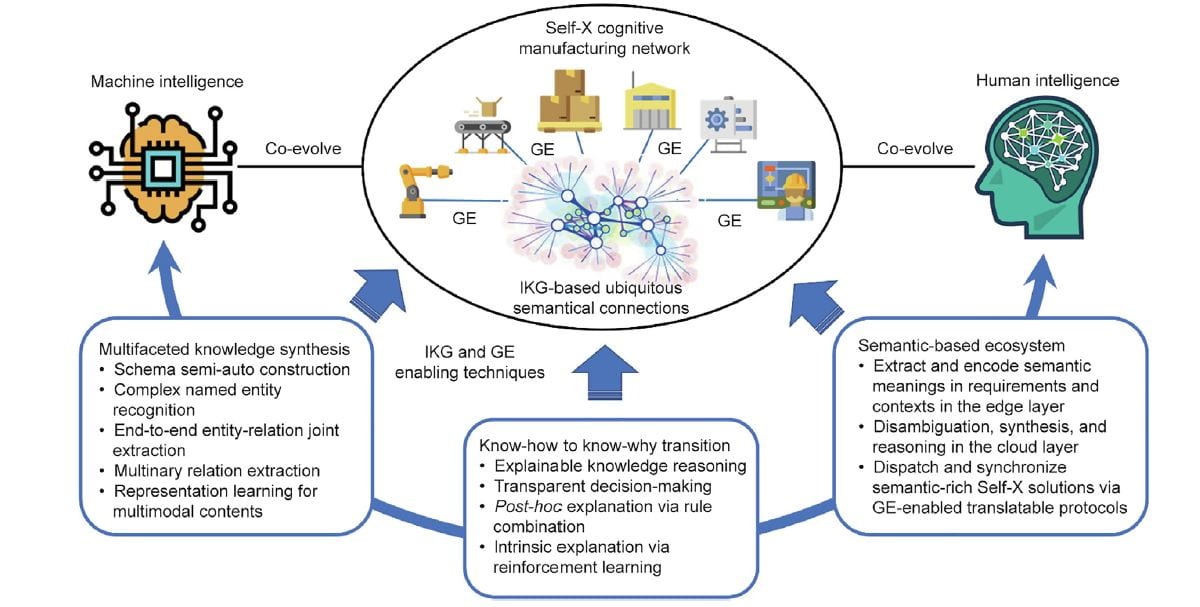

Industrial Artificial Intelligence

Exploring artificial intelligence potentials for smart manufacturing applications

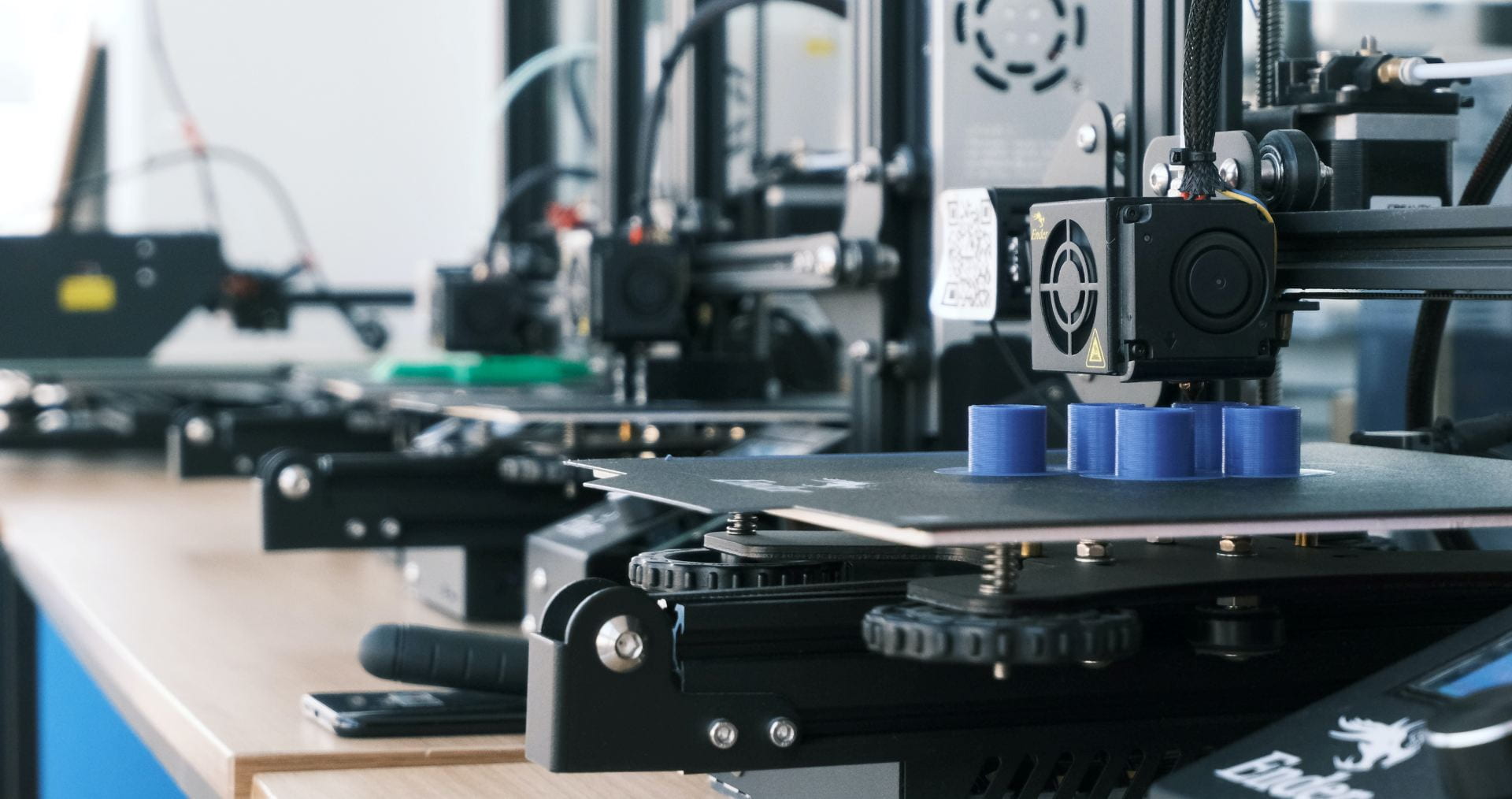

Additive Manufacturing

Use 3D printing technology to create parts and assemblies without tooling

Autonomous Robots

Robots perform behaviors or tasks with a high degree of autonomy

Digital Twin Technology

Integrate technology with spatial network graphs to create living digital simulation models that update and change as their physical counterparts change

Cloud Manufacturing

Develop technologies for enabling on-demand manufacturing resource sharing in the cloud

Industrial big data analytics

Harness data science for efficient operations in complex manufacturing context

Smart Decision Making

Decision-making issues for Industry 4.0 such as smart factory modelling, resource scheduling and energy-efficient machining