Laboratory for Industry 4.0 Smart Manufacturing Systems

Laboratory for Industry 4.0 Smart Manufacturing Systems (LISMS) is the leading research institute on Industry 4.0 in New Zealand.

About LISMS

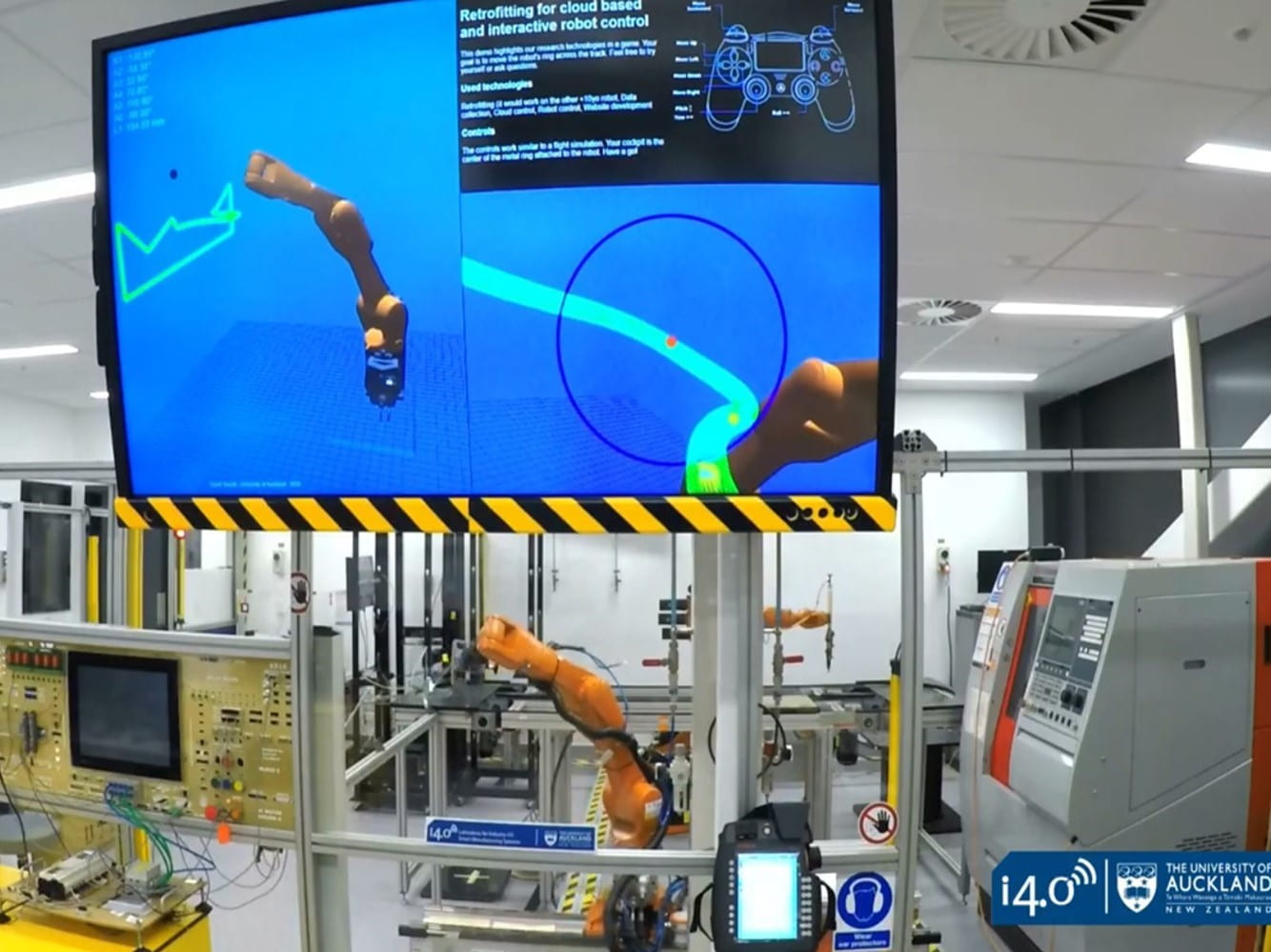

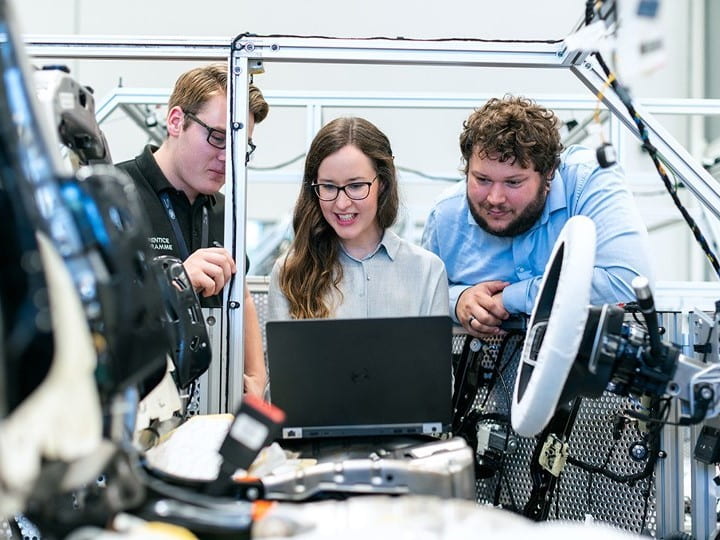

The Laboratory for Industry 4.0 Smart Manufacturing Systems (LISMS) is New Zealand’s first Industry 4.0 Learning Factory. Recognized as the successor to the three earlier Industrial Revolutions, Industry 4.0 represents a smart manufacturing paradigm for the Factories of the Future. Industry 4.0 is ushering in a new era of industrial production whereby technologies such as Industrial Internet, Cyber-physical Systems, cloud computing and analytics, and AI and machine learning are deployed and integrated into production facilities and throughout the operations.

Objectives

Assisting local industries in better understanding Industry 4.0

Educating future engineers with a high readiness level in technologies for industry

Encouraging collaborations between industry and researchers

Showcasing and implementing the research works at local industries

Core Features

Excellence

We deliver high impact and internationally-renowned cloud manufacturing research and technologies.

Impact

We are changing the world by providing innovative and effective solutions to challenges in manufacturing, healthcare, primary industries, service industries, education and fundamental sciences.

Broad capabilities

Our highly talented and diverse team has experience in the field of cloud manufacturing and automation, including in the areas of human-robot interaction, cyber-physical systems, artificial intelligence, digital realities, robotics, and other hardware technologies.

Interdisciplinary

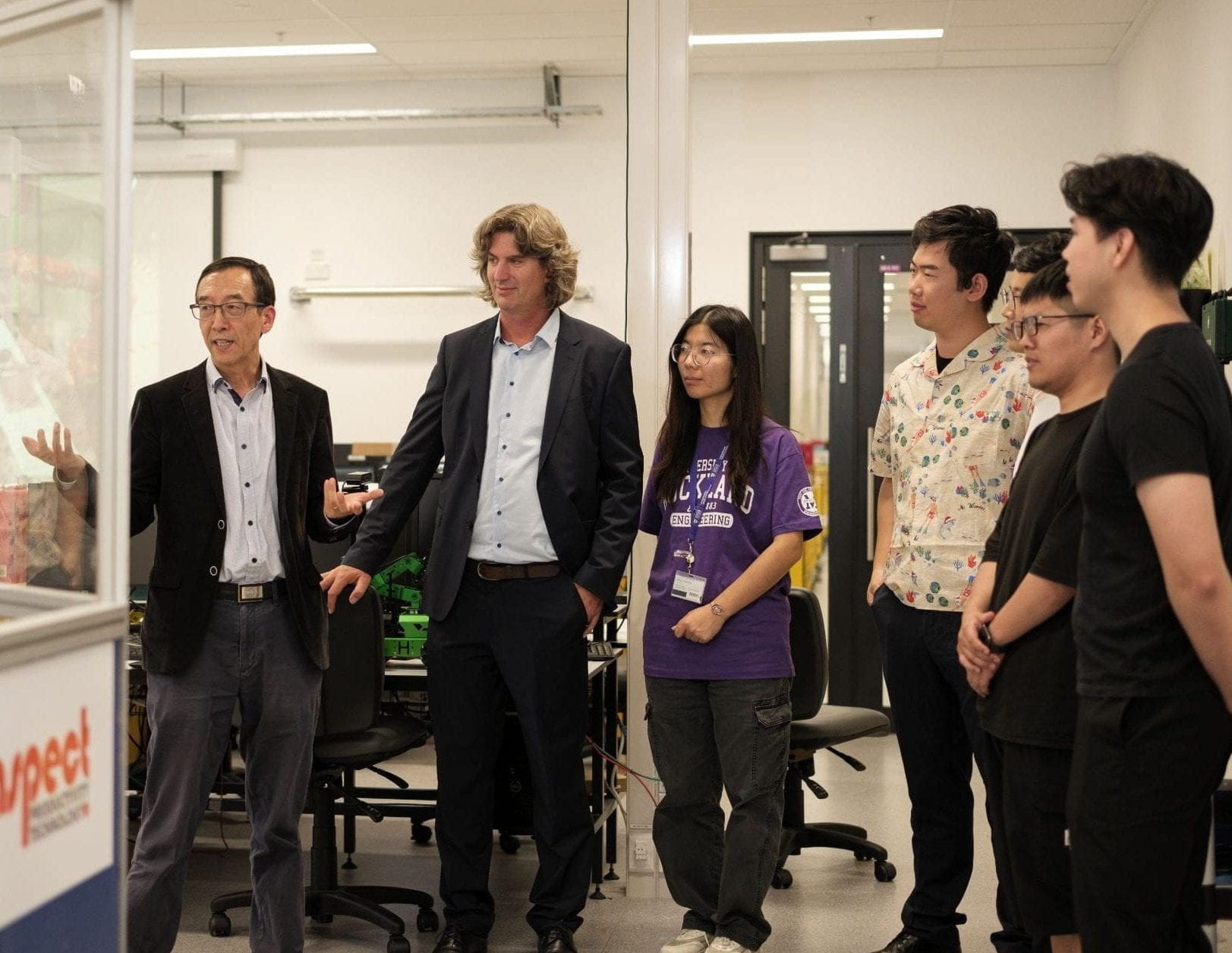

Our team of mechanical and mechatronic engineers and computer scientists are highly collaborative throughout all stages of research.

Global partnerships

Based at the New Zealand’s leading university, we have access to the largest research commercialization company of its kind in Australasia, UniServices, and have established commercial and research partnerships across the globe.

Ideal test bed

Operating within New Zealand, we take advantage of the unique opportunities of a small and heterogeneous market with an accessible regulatory framework, making us an ideal test bed for new technologies.

Research Collaboration

Industry Collaboration

We have a close relationship with the local industry and have worked on a number of collaborative industry projects. Our industrial clients include:

If you think a collaboration with us would be beneficial for your company or organization, if you would like to visit our laboratory or just want to know more about Industry 4.0, do not hesitate to contact us.